Harrington Legionnaire

In September 1963 Harrington announced the launch of a new design. The press release in the respected trade journal Bus & Coach read as follows:

"Plans are now in hand for the production of another coach body for the Bedford VAL six-wheeled, twin-steer chassis for next season. Named Legionnaire, it has been evolved by Thomas Harrington Ltd., the Hove, Sussex, coachbuilding concern, as an addition to its established range of bodies. Harrington has specialized for many years in all metal construction, and has an established department for producing glass fibre mouldings. This experience is being applied to the Legionnaire body, the structure of which is largely of light alloys and steel, with plastic mouldings for such shaped parts as the front panel, the rear corner panels, front and rear roof domes and the wheel arches. From drawings I judge the appearance of the new coach to be attractive. Three windows on both sides, each nearly 7ft. wide together with deep wrap-round screens front and rear, give promise of excellent passenger visibility. Such large areas of glass are heavy. Nevertheless the estimated weight of the 36ft. by 8ft 2½in well-equipped body with 52 seats is commendably low at 3 tons 3cwt."

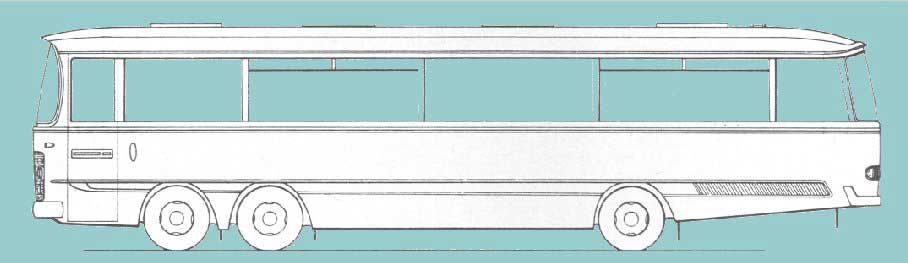

Pictured above is body number 2913. Registered 100 BRU it featured in early Harrington advertising for the Legionnaire.

From the styling point of view the big advantage was the novelty of the three axle layout of the VAL chassis. Apart from the over large grille on the front (a styling trend enjoying favour on almost all manufacturer's designs) the whole vehicle was a step forward in modernity. Unfortunately, at the time it attracted criticism for being too box like. If only the critics could have imagined service buses of the 1990s to know what boxy really meant. The roof was squared off at the sides but tapered down at each end as can be seen in the line drawing at the top of the page. This, and the gentle rise of the bottom edge after the rear wheels combined to give a more delicate effect than a plain box. At the back the

Grenadier fibre glass rear panel was employed but in order to allow the maximum height for the rear windows, did not include the glass panel which normally displayed the operator's name. This was placed in a separate enclosure behind the rear seat and viewed through the window. The boot was so large that two access hatches were provided on each side as well as the patent Harrington cantilever boot lid. As with previous models, the aluminium trim used around the outside waist-rail was supplied by the German firm Happische but for the Legionnaire was a wider design not seen before.

Although Smiths forced air ventilation was used (the intakes being under the peak above the windscreen) sliding top vents were used on two of the large side windows.

It did not take Ford long to develop their 570 Thames psv chassis to enable fitting of 36' long bodies. This was known as the Thames 676 and by 1964 the Legionnaire was available on the Thames in Mk1 form. It has to be said that the appearance became less sleek when mounted on the Thames chassis. Small factors all conspired to take away the long low look of the Bedford version. First, the coach was indeed, not so low. The Ford chassis required that some two inches in height be added to the body and this may be seen just above the front side lights which are no longer equidistant between the waist trim and grille. Larger wheels meant larger arches which cut through the top line of the side trim so it no longer ran front to back in an unbroken line. Finally of course, and probably unintentionally, Bedford had really scored with the number of axles on the VAL chassis which seemed to add a certain something to break up the slab sides and lift the designs of all coachbuilders.

Harrington Legionnaire Mk 2

At the end of 1964 the Mk 2 Legionnaire was shown at the London Commercial Motor show. The changes were mostly construction detail and may have been Harrington responding to comments from operators.

The obvious difference was the change to the curve of the roof which abandoned the hard formed line of the Mk 1 and changed to the shallow curve which was the same as the Grenadier. Due to this, the interior head room and luggage rack space was reduced which was a bit of a pity. Like the Grenadier, the Mk 2 could be ordered with four perspex glazed panels set into the roof, but the general opinion was that on all vehicles this led to the interiors becoming oppressively hot.

This may be some reflection on the dubious efficiency of the Smith's forced air ventilation system generally coming into common use on many coachbuilders designs at this time. For the Mk 2 Legionnaire this system was standard and the opening side windows were deleted. This undoubtedly gave the coach a much cleaner appearance but the air intakes in the peak just over the windscreen may not have been adequate replacement. It is worth mentioning that after the end of Harrington coach building the Plaxton Panorama design resorted to quite large air scoops on the roof to get enough air into the coach.

Slightly more subtle was the fact that the body panels were no longer fastened with rivets. They reverted to a fairly commonly used system where the aluminium is literally nailed into position and then a vertical aluminium "strap" is secured across the join. In the Mk 2 Legionnaire, wood was fastened to the main aluminium framing to allow this to be done. Many operators were of the opinion that rivetted construction looked "cheap" and bus-like. Coaches were expected to have strapping - which in Harrington's case, since the thirties, had cunningly hidden the securing screws. Cavalier panels had always used countersunk rivets straight into the frame and then this was concealed by strapping. There are many technical arguments both for and against rivetted construction but popular opinion is that in this instance the change to the Legionnaire was cosmetic, even if the security of the panel appeared slightly less. It is also possible that the Mk 1 rivetted construction had not stood up well to the flexing that was to be found in both the Ford and Bedford chassis, due to their lightweight construction. Under these circumstances, rivets will move and elongate their holes unless the body construction is specifically designed to take all the stress. This may be the reason that Harrington reverted to wooden fastening instead of the Cavalier method which was in fact simpler.

Only some 58 Legionnaires of all sorts were made, including two rather special items on Guy chassis. This probably reflects the limitations imposed by the size of the factory rather than any suggestion that it was an unpopular design. In most instances it was selling in orders of one or two, when the Grenadier order book was routinely made up of batches of at least four and maybe up to a dozen at a time. In these circumstances, scheduling precious space for a run of the Legionnaire would have been a secondary consideration. The last Legionnaire appears to have been made in July 1965, before the final announcement to cease coachbuilding was made.